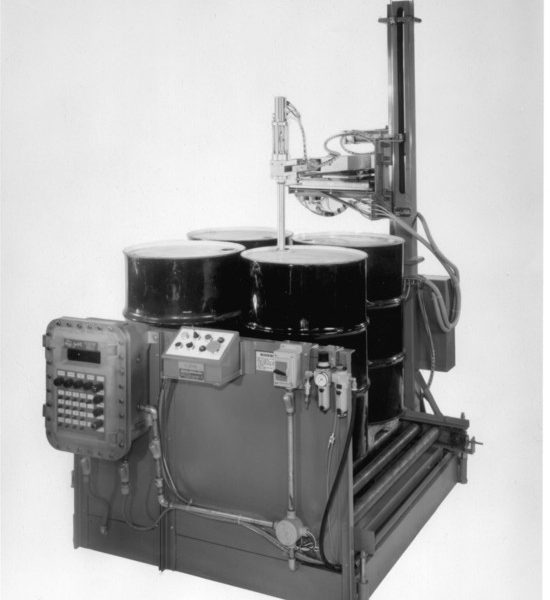

Model Description

OPERATION:

The operator places all bung openings toward the center of the pallet with the caps out. Roll pallet on filling platform. The operator aligns filling lance to drum opening. He then presses the start button; the electronic scale auto tares and the filling lance will descend to the bottom of the drum and start the filling cycle. After a time period, the lance will start to rise and will stop before it comes out of the drum. When all four drums are filled, the operator exits pallet and starts operation on another set.

AVAILABLE OPTIONS:

- Infeed Discharge Conveyor: 5 ft. min to 10ft gravity conveyor sections. Powered rollers on fill platform;

- Full Stoke filling head: Allows full movement of head to corners of fill scale. (Needed for 16 gallon kegs on pallet machine);

- Coatings available: 304 SS, two part epoxy spray coated or Steelit paint. Enamel paint is standard;

- Explosion proof electrics for use in hazardous environments. NEC classifications, Class 1, Div. 1, Groups C&D. Class 11, Div. 1, Groups E,F&G Class III;

- Operator splash guard;

- Fume covers.

Reviews

There are no reviews yet.