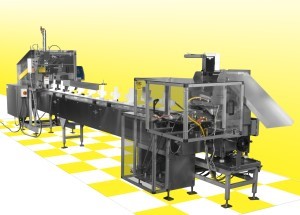

Model Description

The T-System’s method of operation is:

- Flat blank is automatically pulled from a supply magazine with vacuum cups;

- Flat blank is feed forward to forming area via a set of feed fingers;

- A mandrel plunges the blank through a tooling cavity where it is corner glued, corner locked or folded over;

- The completed formed tray is discharged straight down on to a variable speed, continuous motion, flighted conveyor;

- The standard machine has 6 feet (1830mm) of load area for an operator or robot to load product in to the formed trays;

- The loaded tray is transferred 90 degrees in to the Reverse Triseal or Straight Line Closer where the tray is sealed with hot melt glue and discharged from the machine.

OPTIONS:

- Extended or reduced sized cartons outside the standard range;

- Adjustable magazine;

- Extended conveyor length;

- Intermittent Motion drive for conveyor;

- Deboss, Ink and hot leaf coding system;

- 3 light beacon;

- 5’ extended carton magazine;

- CE Guarding.

Reviews

There are no reviews yet.